Description

hardware flow control. It is an ideal choice in the field of industrial automation.

In June 2018, Yaskawa (China) Robot Co., Ltd. held a completion ceremony for its third factory in Changzhou. In October, Japan”s FANUC Robotics Chongqing base

project started construction and is expected to be completed in the first half of 2019. After reaching capacity, it will achieve an annual output value of more than 200

million yuan. Local areas compete for new opportunities in high-end manufacturing

From government procurement and local industrial policies, we can see that all regions are competing for new opportunities in digital and intelligent transformation,

and high-end manufacturing, represented by robots, has become the focus of local efforts.

At the CIIE, robot companies received intensive orders. Analysts from the 21st Century Economic Research Institute found that high-end manufacturing, smart

and high-end equipment, new energy vehicles, etc. have become the focus of procurement in the procurement lists of multiple provincial trading groups.

Official data shows that of the US$57.83 billion in intended turnover at the CIIE, the smart and high-end equipment exhibition area had the highest turnover, reaching

US$16.46 billion. Some exhibitors at the exhibition said that they had never received so many large customers from state-owned enterprises and local governments in

one day, and the total order volume far exceeded expectations.

The representative city that focuses on high-end manufacturing is Shanghai, where the service industry accounts for more than 70%. In the “Thirteenth Five-Year

Plan for the Transformation and Upgrading of Shanghai”s Manufacturing Industry” released at the end of 2016, high-end manufacturing is regarded as an important

breakthrough for industrial transformation.

In the past two years, Shanghai”s investment promotion in the field of high-end manufacturing has also been fruitful. A number of major projects such as robots,

new energy vehicles, large aircraft, and integrated circuits have been launched one after another. Take robots as an example. As a carrier of intelligent manufacturing,

Shanghai has gathered domestic and foreign leading robot companies including ABB, KUKA, SIASUN and Xinstar. Currently, robot output accounts for more than 20% of the country”s total.

In the first half of 2018, Shanghai”s non-state-owned economic and industrial investment increased by 32.9% year-on-year, with major projects distributed in various

industries such as auto parts, clothing, and robots. High-end manufacturing projects introduced in Shanghai this year include the Tesla Gigafactory, which plans to

produce 500,000 pure electric vehicles per year , and the

ABB Robotics Gigafactory, which plans to produce 100,000 robots per year. The latter will realize “making robots with robots”. After being put into production in 2020,

the total output of high-end industrial robots made in Shanghai will double.

As a manufacturing hub in the central and western regions, Chongqing is also making continuous efforts in high-end manufacturing. In 2018, Chongqing held the first

China Smart Expo, focusing on smart manufacturing and hoping to build a project exchange and docking

platform in the field of smart manufacturing. In November, Chongqing released “Nine Policy Measures to Reduce the Cost of Manufacturing Enterprises”, which will

reduce the cost of manufacturing enterprises by more than 30 billion yuan each year. Chongqing also supports key enterprises to increase their efforts in intelligent

transformation of equipment, with a maximum subsidy of 5 million yuan for a single project.

In terms of project investment, three of the four major robot families have settled in Chongqing to invest, including ABB from Switzerland, KUKA from Germany, and

FANUC from Japan. At present, there are more than 300 robot companies in Chongqing, and the number of industrial robot companies has exceeded 120.

A mature robot market should have 70 robots per 10,000 jobs. Countries with relatively developed robot applications, such as South Korea, Germany, Japan, etc.,

already have 300 robots per 10,000 people, while China is far lower than the previous one. numbers, let alone compared to developed countries. In 2016, China”s

“Robot Industry Development Plan (2016-2020)” proposed that the density of industrial robots (the number of industrial robots used per 10,000 workers) should reach more than 150 by 2020.

How to support high-end industries locally

Analysts from the 21st Century Economic Research Institute combed through the high-end manufacturing support policies in Shanghai, Chongqing,

Shandong and other places and found that most of them focus on industrial land, fiscal and tax support, etc.

Shanghai has proposed seven safeguard measures: reforming the industrial system and mechanism, coordinating industrial land use,

increasing fiscal and taxation support, promoting the integration of industry and finance, building a talent system, implementing an open development

strategy, and improving the planning and implementation system. Jiangsu implements a high-end equipment research and development catch-up project,

focusing on the development of 13 fields such as electronic industry equipment and intelligent complete sets of equipment.

Zhejiang implements special projects for equipment with major shortcomings, focusing on ten major fields such as rail transit, robots and

intelligent manufacturing equipment.

https://www.xmamazon.com

https://www.xmamazon.com

https://www.plcdcs.com/

www.module-plc.com/

https://www.ymgk.com

DAPC100 3ASC25H203 | ABB | Control panel kit

DSDI303 57160001-CX | ABB | Digital input module

PPC905AE101 3BHE014070R0101 | ABB | PC board

PPC902AE101 3BHE010751R0101 | ABB | Circuit board module

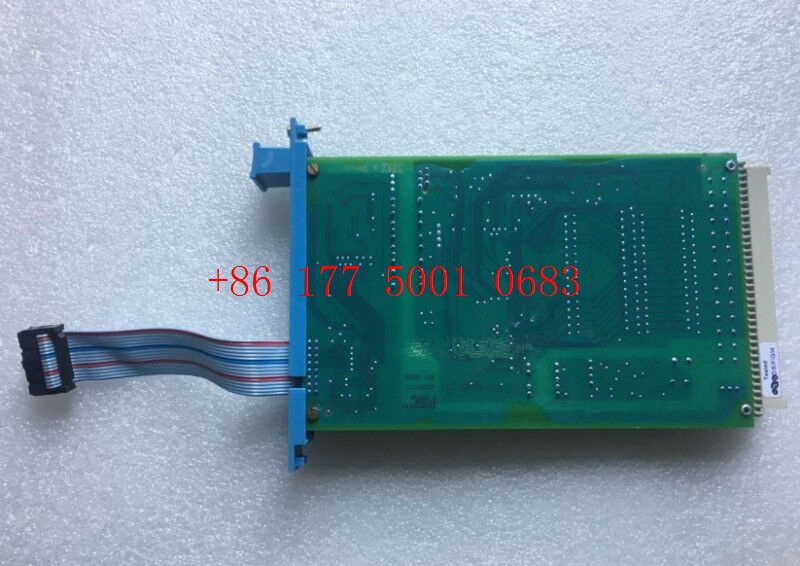

PPC380AE01 HIEE300885R1 | ABB | High voltage circuit board

PPC380AE02 HIEE300885R0102 | ABB | processing unit

PPC902CE101 3BHE028959R0101 | ABB | High voltage circuit board

PPC322BE HIEE300900R0001 | ABB | PP C322 BE1 processing unit

PFRL101D-5kN | ABB | PFRL 101D-5kN load cell

TC513V1 3BSE018405R1 | ABB | modem

DI86-32 57275782 | ABB | Digital input module

DC551-CS31 1SAP220500R0001 | ABB | Bus module

PXAH401 3BSE017235R1 | ABB | Operating panel

CMA125 3DDE300405 | ABB | Pulse amplifying plate

HEDT300272R1 ED1782 | ABB | Pulse input module

HEDT300813R1 ED1633 | ABB | Frequency converter accessories

HEDT300340R1 ED1780A | ABB | Bus repeater module

HEIA303892R1 ED1251A | ABB | Communication module

DP620 3BHE300016R1 | ABB | Power module

VD86-AMP 572B8001 | ABB | Programmable controller

YPQ203A 3ASD510001C17 | ABB | Robot board

DSPC171 57310001-CC | ABB | System module backplane

CT302A GJR2167200R0001 | ABB | CPU processor

HESG447260R2 70BA01C-S | ABB | Processor power module

HEDT300254R1 ED1790 | ABB | Digital I/O module

YPM106E YT204001-FN | ABB | Power electronic module

UNS4881BV1 3BHE009949R0001 | ABB | Ethernet module

UNS4881b,V4 3BHE009949R0004 | ABB | Thermal resistance power module

UNS2980c-ZV4 | ABB | Pulse amplifier plate

UNS2882A 3BHE003855R0001 | ABB | Pulse trigger plate

UNS0874C V.1 3BHB002651R1 | ABB | Power connection board

UNS0874A | ABB | Numerical control module

UNS0122A-P | ABB | Processor end module

UNS0119A-P,V101 3BHE029153R0101 | ABB | Communication control panel

UNS0007A-P V1 | ABB | Digital I/O card

UFC092A V1 HIEE300686R1 | ABB | Channel digital output module

SPNIS21(NIS21) | ABB | Network interface module

SPFEC12 | ABB | AI module

SPFCS01 | ABB | Frequency Counter Module

SPBRC410 | ABB | controller

SPASO11 | ABB | AO Module

SDCS-UCM-1 | ABB | Extension plate

SDCS-POW-1C | ABB | Power supply panel

SDCS-PIN-48-SD | ABB | Pulse transformer plate

SDCS-IOE-1 | ABB | Wiring terminal

SDCS-IOB-23 | ABB | Digital connecting plate

SDCS-COM-1 3BSE005028R0001 | ABB | Driver link board

SAFT-190-APC | ABB | Driver module

SAFT-185-TBC | ABB | Control module

Reviews

There are no reviews yet.