Description

hardware flow control. It is an ideal choice in the field of industrial automation.

According to reports, ABB”s technical expertise and experience in many industries will be combined with Microsoft”s Azure intelligent cloud system and B2B

engineering capabilities to create greater value for customers. Combined with ABB”s more than 70 million connected devices installed globally and more than

70,000 running control systems, ABB and Microsoft will join forces to create one of the world”s largest IIoT industrial cloud platforms.

It is worth noting that IoT expert Guido Jouret (formerly general manager of Cisco’s IoT department) became the group’s chief digital officer on October 1, 2016.

This marks that ABB is accelerating digital transformation and comprehensively building a new “Internet of Things+” ecosystem. ABB also hopes to obtain higher

profits from this, and has proposed a financial target for 2015-2020 of pre-tax profit growth of 11%-16%.

FANUC

FANUC recently established the IoT platform Fanuc Intelligent Edge Link and Drive (FIELD), which uses NVIDIA artificial intelligence system. FIELD can realize the

connection of machine tools, robots, peripheral equipment and sensors in the automation system and provide advanced data analysis to improve the production quality,

efficiency, flexibility and equipment reliability in the production process – thereby improving the overall efficiency of the equipment ( OEE) and promote the improvement of production profits.

The system can also improve robot productivity through artificial intelligence and bring autonomous learning capabilities to automated factory robots around the

world. FANUC will use a series of GPUs and deep learning software designed and produced by NVIDIA to enable AI artificial intelligence to be used in clouds, data centers

and embedded devices.

When talking about the cooperation with FANUC, NVIDIA co-founder and CEO Jensen Huang said that the era of AI artificial intelligence has officially arrived.

Through the deep learning function of GPU, it will stimulate a

new wave of software learning and machine inference calculations. The most exciting of these is the ability of robots to understand their surroundings and

interact with humans. NVIDIA is very happy to work with FANUC, the global leader in automated factories and robots, to build intelligent machines to benefit the future of mankind.

It is reported that FIELD continues the success of the existing Fanuc ZDT (zero downtime function), which effectively combines Cisco cloud technology,

IoT data collection software and point-to-point security. After connecting the robot through the use of an industrial Ethernet switch, it is then connected to Cisco”s UCS server – the system runs

based on FANUC and Cisco”s ZDT data collection software. Automotive industry users can immediately realize reductions in downtime and cost savings after using the system.

FIELD provides users and application developers with advanced machine learning and artificial intelligence capabilities and brings manufacturing to

new heights of productivity and efficiency. Currently, FANUC has applied these new technologies to robotic bulk picking, production anomaly detection and fault

prediction. Because FIELD combines artificial intelligence and cutting-edge computer technology, distributed learning is possible. The operating data of robots and

equipment are processed in real time on the network,

which also enables more intelligent coordination of production between various equipment, making complex production coordination that was previously difficult to

achieve easily completed.

In fact, many years ago, FANUC began to cooperate with Cisco to carry out the “non-stop” zero downTIme plan. In the plan, FANUC and Cisco will join forces to

build an Internet of Things system that will allow FANUC to supervise

every robot in the factory, predict abnormal conditions of the robots, and send more technicians to repair the robots before problems occur. So far, the program has

tested 2,500 robots, including FANUC”s major customer GM General Motors. According to FANUC, the test program saved customers $38 million.

YASKAWA

After talking so much about the Internet of Things strategy of the industrial robot giant, let’s take a break here at Yaskawa and talk about the past.

Midea and KUKA have officially received their marriage certificates, but you must know that as early as August 2015, Midea announced its

robot strategy and established two joint venture subsidiaries with Japan”s Yaskawa Electric.

The two subsidiaries are respectively for industrial robots and service robots, including Guangdong Yaskawa Midea Industrial Robot Co.

, Ltd. (Midea”s equity accounted for 49%) and Guangdong Midea Yaskawa Service Robot Co., Ltd. (Midea”s equity accounted for 60%).

This shows that as early as 2015, Midea was actually “in love” with Yaskawa, but by 2016, she married Kuka.

https://www.xmamazon.com

https://www.xmamazon.com

https://www.plcdcs.com/

www.module-plc.com/

https://www.ymgk.com

1783-BMS10CA managed Ethernet switch

VE4003S2B6 Analog input card

IC200UDR005 28-point mini PLC module

IC754VSI12CTD-EG Operation panel

VE4033S2B1 Redundant analog input card

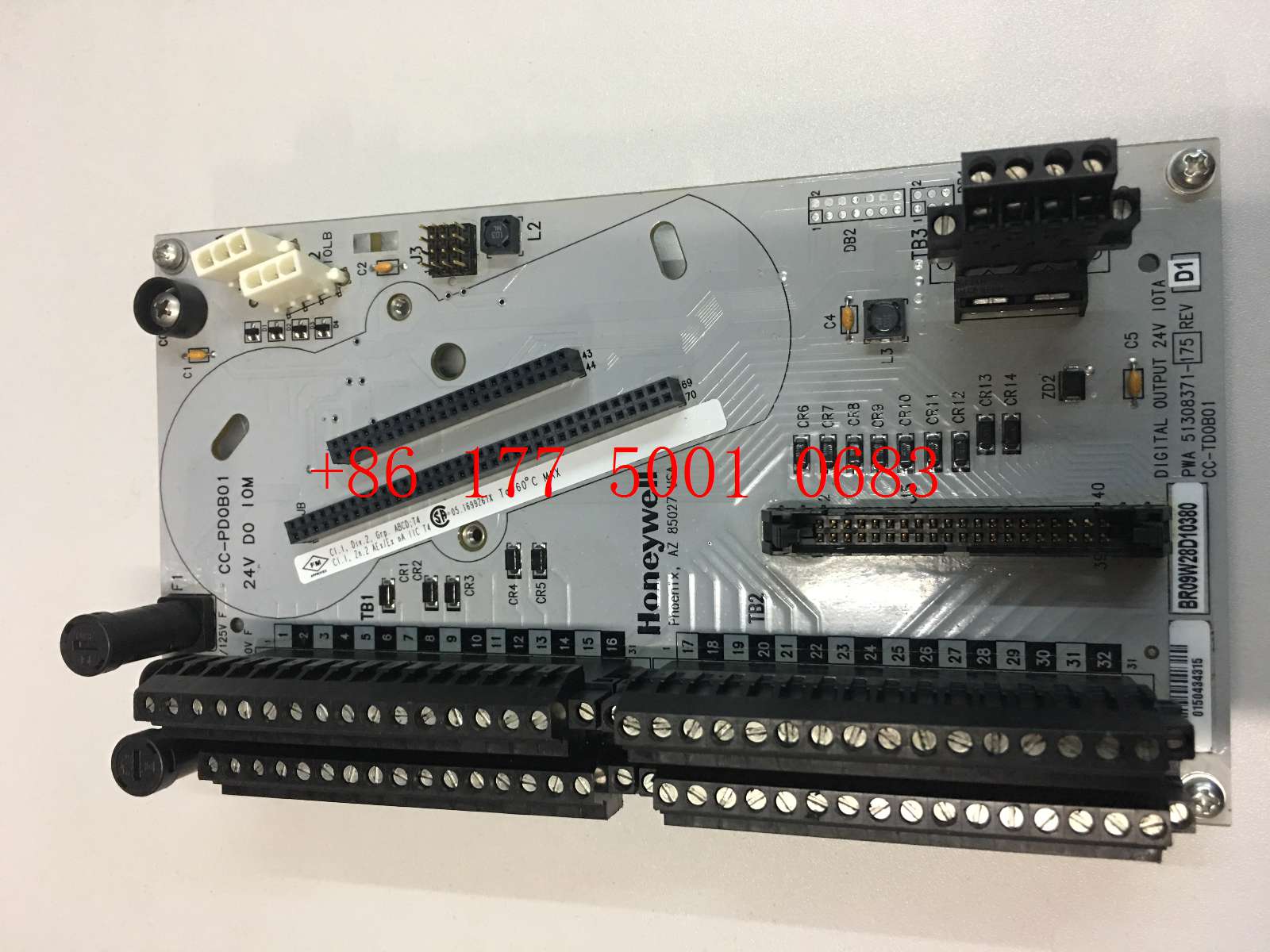

8C-PDILA1 HONEYWELL control system switch module

NDCU-21C drive control unit 42000652 ABB

IC695ALG808 Isolates the analog output module

PLX31-EIP-MBS Modbus serial communication gateway

IC695ALG508 Isolates the RTD input module

PCIE-6351 Multifunctional I/O device

IC694MDL930 Relay output module

1756-L73XT/B ControlLogix-XT controller

DX61B0075-5A3-4-00 SEW servo drive

DS200IIBDG1AGA insulated gate bipolar transistor

E69F-TI2-JS current-pneumatic converter

VMIVME-4512 Analog I/O board

MC4/11/10/400 ELAU Motion controller

61866-15pt High performance industrial display

MTL5553 MTL Instrument isolator/Power supply

MTL838C MTL instrument analog transmitter

810-099175-011 LAM Interface board module

DSQC346G 3HAB8101-706B drive unit

5PC810. SX05-00 APC810 system unit

XV 430-12TSB-1-10 EATON 12.1″, TFT color

XV440-10TVB-X-13-1 EATON 10.4 “, TFT color

XV 430-10TVB-1-10 EATON 10.4 inches

XV442-57CQB-X-13-1 ESTON 5.7 inches

XV 432-57CQB-1-10 ESTON 5.7-inch touch screen

XV-440-12TVB-1-50 EATON

XV 440-12TSB-1-10 ESTON Touch panel

XV-440-12TVB-1-50 EATON Man-machine interface

XV 440-12TSB-X-13-1 ESTON 12.1″, TFT Color, i/r, Ethernet, USB, RS232, CANopen

XV442-57CQB-1-10 EATON 5.7 inch, Color, i/r, Ethernet, USB, RS232, CANopen

VE3008 CE3008 KJ2005X1-MQ1 12P6381X042 MQ Controller

05074-A-0122 05704-A-0121 05704-A-0131 honeywell Quad Relay Interface Card

136294-01 BENTLY 3500/62 I/O Module

P0926PA FOXBORO FBM224, FBM230, and FBM231 terminals

VBX01TA ABB Bus Extender

F3430 HIMA Input/output module

P0916FK FOXBORO cable

140471-01 3500/42M I/O Module

F3430 HIMA Relay module F 3430

3500/91-01-01(161204-01+161216-01)bently Communication Gateway Module

LENZE EPL10200-W includes EPZ-10203 CANPT010W3E

UNS0119A-Z,V1 3BHE030579R0001 Automatic voltage regulator

UNITROL 1020 3BHE030579R0003 Indirect Excitation System

UNS0119A-Z,V1 3BHE030579R0001 Automatic voltage regulator

LAIB V3.0_A00 034STN1-01-300-RS

Reviews

There are no reviews yet.