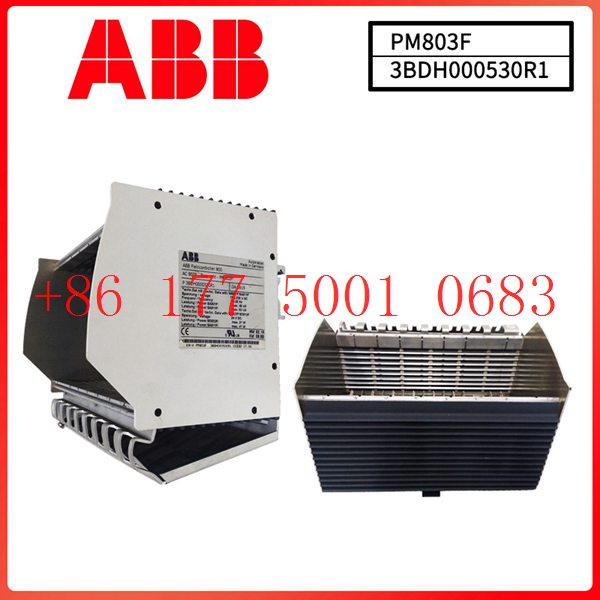

Description

hardware flow control. It is an ideal choice in the field of industrial automation.

How does ABB robot multi-task? Detailed steps on how to use ABB robot multitasking

1.ABB robots support multi-tasking (each robot body can support up to one motion task).

2. To use multi-tasking, the robot must have the 623-1 mulTItasking option

3. How to create a new multi-task?

4. Control panel, configuration

5.Theme controller

6. Enter the task and create a new one

At this time, it must be set to normal, otherwise programming cannot be performed. After all programming and debugging are completed, set it back to

semi staTIc and it will start running automatically.

7. Restart

8. The program editor enters t2 task.

9. How to transfer data between multiple tasks? The following takes the bool amount flag1 transferred between tasks as an example (that is, if any task

modifies the flag1 value, the flag1 value of the other task is also modified)

10. Both the front-end and the back-end must create data. The storage type must be a variable with the same type and the same name, for example:

Pers bool flag1

That is to say, both tasks must have this flag1, and it must be a variable variable.

11. In t2, the code is as follows

12. The foreground task code is as follows

The above can realize the background task to scan the di_0 signal in real time. If the di_0 signal changes to 1, flag1 is true. According to logic, the front

desk waits for flag1 to be true. After executing waituntil, set flag1 to false

13. How to run?

Click on the bottom one in the lower right corner of the teach pendant, make sure both tasks are checked, and then run it. You can test it.

14. There is no problem in the test. Enter the configuration interface, change t2 to semi staTIc, and restart. At this time, t2 cannot be selected and it has started

running automatically.

Analysis of ABB Robot Simulation Technology

The competitive pressure in the industrial automation market is increasing day by day, and customers are demanding higher efficiency in production to

reduce prices and improve quality. Spending time testing or commissioning a new product at the beginning of a new product is not feasible today because it would

mean stopping existing production to program the new or modified part. ABB”s RobotStudio is built on ABB VirtualController. We can use it to easily simulate the

on-site production process on the computer, allowing customers to understand the development and organization of the production process.

robotstudio features:

1. CAD import

RobotStudio can easily import data in various mainstream CAD formats, including IGES, S TE P, VRML, VDAFS, ACIS and CA TI A, etc. Robot

programmers can use these precise data to program robots with higher accuracy, thus improving product quality.

2. Automatic path generation

One of the most time-saving features in RobotStudio. By using a CAD model of the part to be processed, this function can automatically

generate the robot position (path) needed to track the machining curve in just a few minutes, a task that would normally take hours or even days.

3. Program editor

The program editor (Program Maker ) can generate robot programs, allowing users to develop or maintain robot programs offline in

a Windows environment, which can significantly shorten programming time and improve program structure.

4. Path optimization

The Simulation Monitor is a visual tool for robot motion optimization, with red lines showing where improvements can be

made to make the robot operate in the most efficient way.

5. Automatically analyze stretching ability

Users can use this function to move the robot or workpiece arbitrarily until all positions are accessible, and the work

cell floor plan verification and optimization can be completed within minutes.

6. Collision detection

Collision detection function can avoid serious damage caused by equipment collision. After selecting detection objects,

RobotStudio can automatically monitor and display whether these objects will collide when the program is executed.

7. Online homework

Use RobotStudio to connect and communicate with real robots, and perform convenient monitoring, program modification,

parameter setting, file transfer, backup and recovery operations on the robot.

https://www.xmamazon.com

https://www.xmamazon.com

https://www.plcdcs.com/

www.module-plc.com/

https://www.ymgk.com

“WOODWARD 5501-466 Digital Microprocessor Controller”

“WOODWARD 5501-372”

“WOODWARD 5501-367 – Micronet Simplex LV Discrete FTM”

“WOODWARD 9905-463”

“WOODWARD 9905-373”

“WOODWARD 9905-973”

“WOODWARD 9905-003”

“WOODWARD 9905-211”

“WOODWARD 9905-462”

“WOODWARD 9905-970”

“WOODWARD 9905-096”

“WOODWARD 9905-373”

“WOODWARD 9905-020”

“WOODWARD 9905-017”

Woodward 9905-021 2301A Series Load Sharing & Speed Control

“WOODWARD 9905-301”

“WOODWARD 9905-144”

“WOODWARD 9905-148”

“WOODWARD 9905-030”

“WOODWARD 9905-867”

“WOODWARD 9905-003”

“WOODWARD 9905-971”

“WOODWARD 9905-726”

“WOODWARD 9905-144”

WOODWARD 5464-414

WOODWARD 5466-258

WOODWARD 5466-316-Analog Combination Module

WOODWARD MicroNet Pentium CPU Module 5466-409

WOODWARD 5501-467 Power Supply Board

WOODWARD 5501-470

WOODWARD 5501-471

WOODWARD 8200-1300 Integrated Graphics Control Panel

WOODWARD 8237-1006

WOODWARD 8237-1600

WOODWARD 8402-119

WOODWARD 8402-319

WOODWARD 8402-319 8402-119

WOODWARD 8440-1713

WOODWARD 8440-1713/D

woodward 8444-1067C

woodward 8444-1067

8446-1019 D RP3000 RP-3200-P2

woodward 8446-1019

woodward 8701-758 5601-1126

woodward 9905-973

woodward 9907-149

woodward 9907-162

woodward 9907-164

woodward 9907-165

woodward 9907-167

woodward EASYGEN-3500-5/P2 8440-2145

woodward 9907-252

woodward 9907-838

woodward EASYGEN-3500-5/P2 8440-2145

WOODWARD EGCP-3 8406-113 Digital Control Operator Interface

woodward TG-13(8516-038) 4-314871-1

PPD113B03-26-100100 3BHE023584R2625

3BHE023584R2625 CPU processor

PPD113B03-26-100100 CPU processor

3BHE022293R0101 Excitation control module

PCD232A101 Excitation control module

PCD232A101 3BHE022293R0101 ABB

Reviews

There are no reviews yet.