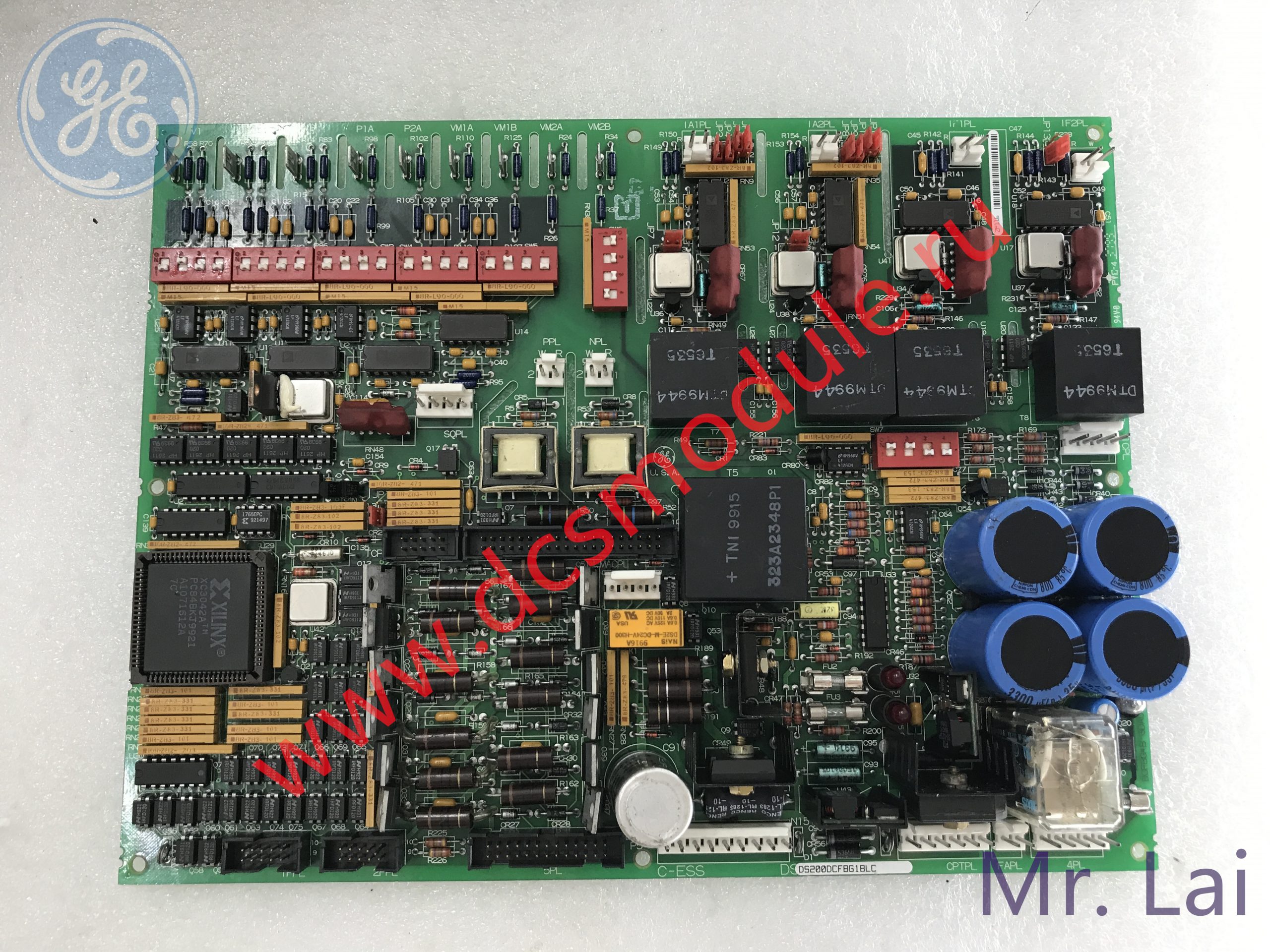

Description

DS200ADMAH1A Boards & Turbine Control Module

высотой 3U, расположенный в раме управления под DSPX.

волоконно – оптический разъем на передней панели и передаются в модуль обнаружения заземления.

ABB: Запасные части для промышленных роботов серии DSQC, Bailey INFI 90, IGCT, например: 5SHY6545L0001 AC1027001R0101 5SXE10 – 0181, 5SHY3545 L0009, 5SHI3545L0010 3BHB013088 R0001 3BHE009681R0101 GVC750BE101, PM866, PM861K01, PM864, PM510V16, PPD512, PPPD113, PP836A, P865A, 877, PPP881, PPPP885, PPSL500000 4 3BHL00390P0104 5SGY35L4510 и т.д.

General Electric: запасные части, такие как модули, карты и приводы. Например: VMVME – 7807, VMVME – 7750, WES532 – 111, UR6UH, SR469 – P5 – HI – A20, IS230SRTDH2A, IS220PPDAH1B, IS215UCVEH2A, IC698CPE010, IS200SRTDH2ACB и т.д.

Система Bently Nevada: 350 / 3300 / 1900, предохранительные зонды и т.д., например: 3500 / 22M, 3500 / 32, 3500 / 15, 3500 / 23500 / 42M, 1900 / 27 и т.д.

Системы Invis Foxboro: Серия I / A, управление последовательностью FBM, трапециевидное логическое управление, обработка отзыва событий, DAC,

обработка входных / выходных сигналов, передача и обработка данных, такие как FCP270 и FCP280, P0904HA, E69F – TI2 – S, FBM230 / P0926GU, FEM100 / P0973CA и т.д.

Invis Triconex: Модуль питания, модуль CPU, модуль связи, модуль ввода – вывода, например 300830937214351B, 3805E, 831235114355X и т.д.

Вудворд: контроллер местоположения SPC, цифровой контроллер PEAK150, например 8521 – 0312 UG – 10D, 9907 – 149, 9907 – 162, 9907 – 164, 9907 – 167, TG – 13 (8516 – 038), 8440 – 1713 / D, 9907 – 018 2301A, 5466 – 258, 8200 – 226 и т.д.

Hima: модули безопасности, такие как F8650E, F8652X, F8627X, F8678X, F3236, F6217, F6214, Z7138, F8651X, F8650X и т.д.

Honeywell: Все платы DCS, модули, процессоры, такие как: CC – MCAR01, CC – PAIH01, CC – PAIH02, CC – PAIH51, CC – PAIX02, CC – PAON01, CC – PCF901, TC – CR014, TC – PD011, CC – PCNT02 и т.д.

Motorola: серии MVME162, MVME167, MVME172, MVME177, такие как MVME5100, MVME5500 – 0163, VME172PA – 652SE, VME162PA – 344SE – 2G и другие.

Xycom: I / O, платы VME и процессоры, такие как XVME – 530, XVME – 674, XVME – 957, XVME – 976 и т.д.

Коул Морган: Сервоприводы и двигатели, такие как S72402 – NANA, S6201 – 550, S20330 – SRS, CB06551 / PRD – B040SSIB – 63 и т. Д.

Bosch / Luxer / Indramat: модуль ввода / вывода, контроллер PLC, приводной модуль, MSK060C – 0600 – NN – S1 – UP1 – NNN, VT2000 – 52 / R900033828, MHD041B – 144 – PG1 – UN и т.д.

(2) Data collection and traceability issues. Data collection issues often occur, and many assembly lines lack “end-to-end traceability.”

In other words, there are often no unique identifiers associated with the parts and processing steps being produced.

One workaround is to use a timestamp instead of an identifier. Another situation involves an incomplete data set. In this case, omit

incomplete information parts or instances from the forecast and analysis, or use some estimation method (after consulting with manufacturing experts).

(3) A large number of features. Different from the data sets in traditional data mining, the features observed in manufacturing analysis

may be thousands. Care must therefore be taken to avoid that machine learning algorithms can only work with reduced datasets (i.e.

datasets with a small number of features).

(4) Multicollinearity, when products pass through the assembly line, different measurement methods are taken at different stations

in the production process. Some of these measurements can be highly correlated, however many machine learning and data mining

algorithm properties are independent of each other, and multicollinearity issues should be carefully studied for the proposed analysis method.

(5) Classification imbalance problem, where there is a huge imbalance between good and bad parts (or scrap, that is, parts that do not

pass quality control testing). Ratios may range from 9:1 to even lower than 99,000,000:1. It is difficult to distinguish good parts from scrap

using standard classification techniques, so several methods for handling class imbalance have been proposed and applied to manufacturing analysis [8].

(6) Non-stationary data, the underlying manufacturing process may change due to various factors such as changes in suppliers

or operators and calibration deviations in machines. There is therefore a need to apply more robust methods to the non-stationary

nature of the data. (7) Models can be difficult to interpret, and production and quality control engineers need to understand the analytical

solutions that inform process or design changes. Otherwise the generated recommendations and decisions may be ignored.

MKD071B-061-GP3-KN REXROTH

REXROTH MKD071B-061-GP1-KN/SA001

MKD071B-061-GP1-KN REXROTH

MKD071B-061-GP0-KN/SA001 REXROTH

MKD071B-061-GG3-KN REXROTH

MKD071B-061-GG1-KN REXROTH

MKD071B-061-GG0-KN REXROTH

MKD071B-035-KP3-KN REXROTH

MKD071B-035-KP1-KN/SA001 REXROTH

MKD071B-035-KP1-KN REXROTH

MKD071B-035-KP0-KN REXROTH

MKD071B-035-KG3-KN REXROTH

MKD071B-035-KG1-KN REXROTH

MKD071B-035-KG0-KN REXROTH

MKD071B-035-GP3-KN REXROTH

MKD071B-035-GP1-KN REXROTH

MKD071B-035-GP0-KN/SA001 REXROTH

MKD071B-035-GP0-KN REXROTH

MKD071B-035-GG1-KN/SA001 REXROTH

MKD071B-035-GG1-KN REXROTH

MKD071B-035-GG0-KN REXROTH

MKD071B-024-GP0-KN REXROTH

MKD071B-024-GG3-KN REXROTH

MKD071B-024-GG1-KN REXROTH

MKD025B-144-KP1-KN REXROTH

REXROTH MKD025B-144-KP0-KN/SA001

MKD025B-144-KG1-UN REXROTH

MKD025B-144-GP0-UN REXROTH

MKD025B-144-GP0-KN/SA001 REXROTH

MKD025B-144-GG1-UN REXROTH

MKD025B-144-GG1-KN REXROTH

MKD025B-144-GG0-UN REXROTH

MKD025B-144-GG0-KN REXROTH

MKD025B-058-KP0-KN REXROTH

MKD025B-058-GP0-KN REXROTH

MKD025B-058-GG1-KN REXROTH

MKD025B-058-GG0-KN REXROTH

MKD025A-144-KP0-KN REXROTH

MKD025A-144-KG0-KN REXROTH

MKD025A-144-GP0-KN REXROTH

MKD025A-144-GG0-KN REXROTH

MKD041B-144-KP1-KN/SA001 REXROTH

MKD041B-144-KP1-KN REXROTH

MKD041B-144-KP0-KS REXROTH

MKD041B-144-KP0-KN/SA001 REXROTH

REXROTH MKD041B-144-KP0-KN

мы организуем фото на складе, чтобы подтвердить

чтобы вернуть их вам. Конечно, мы ответим на ваши озабоченности как можно скорее.

Reviews

There are no reviews yet.